By Glenn Roberts

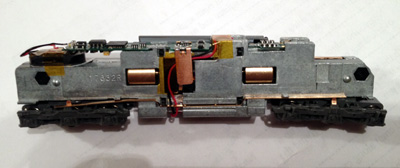

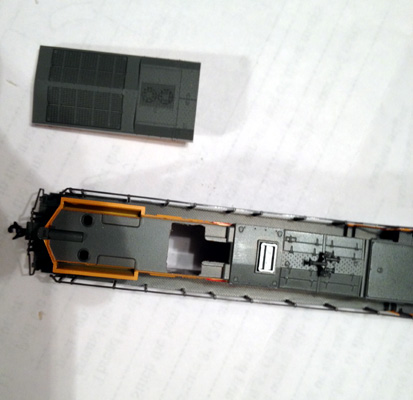

My installation reflects closely what was in the Digitrax manual. The

speaker is located in the rear and the capacitor is in the fuel tank area.

This can be seen in pictures 1 and 2.

One thing that can be seen as a deviation is that the wires for the capacitor are run under the circuit

board power clip and down the side of the fuel tank. A 1/8” end mill was

used to cut the shallow grove used to get the wires to the power clip area.

The ear at the top near the circuit board was also milled back approximately

1/8”. The edge was slightly rounded with a file creating a smooth transition

for the wires to travel over the edge.

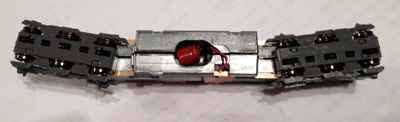

My other deviation can be seen where the capacitor wires run down the side

of the fuel tank. The wires travel behind the brass pickup strip. A 3/16”

end mill was used for this groove. The grove is just deep enough for the

wires and slight clearance. Care was taken to locate the groove between the

plastic motor mount tab and the dimple in the brass pickup strip that helps

hold the strip into the frame.

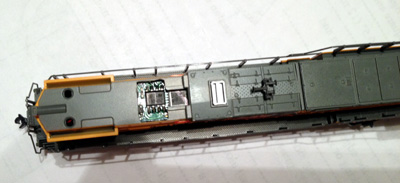

When you look at picture 2 it shows a groove leading to the capacitor

cutout. This groove was also made using a 3/16” end mill. The corner leading

from the side of the frame to the bottom groove was also rounded with a file

to create a smooth transition for the capacitor wires. The capacitor cutout

was made using a 5/16” end mill and the cutout goes through the frame into

the motor area. The frame insulating bushings were not in place when the

cutout was made which makes cutout the slightly wider than 5/16” after

assembling the frame with the insulating bushings in place. One thing that

cannot be seen is that the bottom strap of the plastic motor mount has a

portion cut away to allow the capacitor to fit completely into the cutout.

The fuel tank cover fits nicely by doing this and didn’t need to be trimmed.

The only other modifications done to the frame was to mill away the

triangular protrusions at the end of the frame where the speaker is located.

A file was actually used for this process.

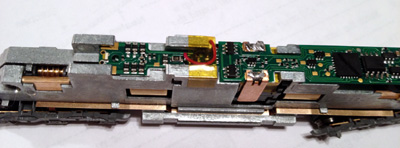

The next process was to modify the shell to provide clearances for the newly

added circuit board. This was a point of frustration but the modifications

are fairly simple after learning what exactly needs to be done.

One point of interference that was discovered was the two chips just in

front of the circuit board power clips. The two chips are just slightly high

and can be seen in image 3.

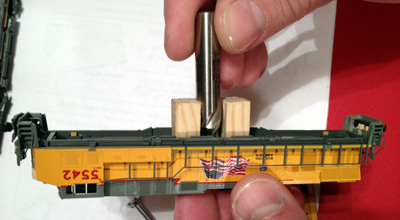

To fix this problem a fixture was made

using two 3/8” square pieces of wood 1-¼” long glued to a 1/16” piece of

plywood. The two 3/8” square pieces of wood were spaced 3/8” apart using a

3/8” end mill. The fixture can be seen in image 4.

By inserting the

fixture into the shell and using the 3/8” end mill turned by hand a slight

amount of the shell can be faced off to provide clearance for the two chips.

This process can be seen in image 5.

Only a slight amount needed to be

removed. This is a tight area for the GEVO shell and this is also the reason

the capacitor wires were routed over the side of the frame instead of

between the circuit board power clips and then over the side.

Another point of shell interference was found with another chip in the

radiator area. To fix this problem the radiator was removed from the shell

and a cutout was added near where the radiator latch engages the shell. This

cutout can be seen in image 6 and in image 7 which shows the shell

placed on the frame.

One last thing that had to be done in this area was

that the speaker needed to be slightly narrowed with a file allowing it to

slip nicely into the shell.

A couple of other shells were also test-fit to this frame. The Kato SD70M

shell fit right on this particular frame without any modifications. The Kato

C44-9W shell needs modifications to fit this particular frame. The problem

with the C44-9W shell is that the chip causing interference in the radiator

area is right on the radiator latch tab. This problem might require gluing

the radiator on due to removing the latch. Care would also need to be used

in removing material from the shell just in front of the radiator latch.

This would be a thin area after removing the proper amount of material. The

exhaust stack also hangs down into the shell of the C44-9W and some of it

also may also need to be removed. I believe the AC4400 radiator is the same

as used on the C44-9W. The same fixes should apply.

I hope this information will be useful to others.

Best Regards,

Glenn Roberts